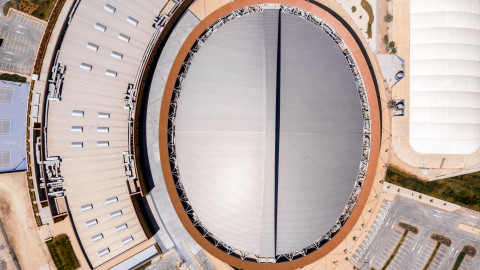

King Saud University Sports Arena

2021Challenges ↑ ↓

The initial design of the Sports Arena was based on the PTFE membrane. A value engineering exercise had to be conducted aligned to the performance requirements of the structure in order to identify an optimal and economical design that would be realized by employing long-lasting materials with a very low maintenance cost. Beyond cost efficiencies, the building’s geometry had to be carefully managed given it had to encompass a large, single-span roof with a central arch truss supporting secondary trusses, and thus vertical and lateral loads had to be given very careful consideration. Design of the Sports Arena roof had to ensure near-perfect acoustics inside the structure, watertightness to ensure zero leakage, and thermal insulation to achieve the specified U-value. A short construction period provided a further challenge as this project was closely monitored by the ministry who had given a concise deadline.

Task ↑ ↓

Located in Riyadh, KSU Sports Arena is an indoor facility specifically built with the needs of athletes in mind. INMA’s task was to install the roof façade and steel structure for the King Saud University Sports Campus Arena. The project involved working in collaboration with respected international consulting engineers Buro Happold to achieve the most cost-effective solution possible. The multi-purpose hall was to accommodate up to 9,400 seated spectators for indoor athletics as well as for conferences.

Solution ↑ ↓

INMA teamed up with Schroeder Associates to redesign the steel structure by utilizing HISTAR steel. The 150m-wide self-supporting roof rests on trellised beams. ArcelorMittal Steel provided high-strength HISTAR grades, which reduces the weight and material costs of steel structures in comparison with conventional structural steel.

A completely new roofing system was suggested and subsequently employed to best meet the proper acoustic and thermal requirements. INMA proposed the Riverclack standing seam metal roof system (providing superior watertightness, walkability and long life to the external metal skin) and this was chosen by the client to replace the PTFE membrane, while proper insulation and decking were carefully selected in coordination with relevant insulation and decking firms.

Result ↑ ↓

“We found working with INMA a superb overall experience. Their technical expertise, combined with professional knowledge and work ethic especially in regard to cladding installation made our lives easier. Together, we managed to achieve the cost efficiencies the client was aiming for and we consider this project a job well done. We would recommend them to any prospective clients or partners in the future.”